-

Lily Lee

Hi there! Welcome to my shop. Let me know if you have any questions.

Lily Lee

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

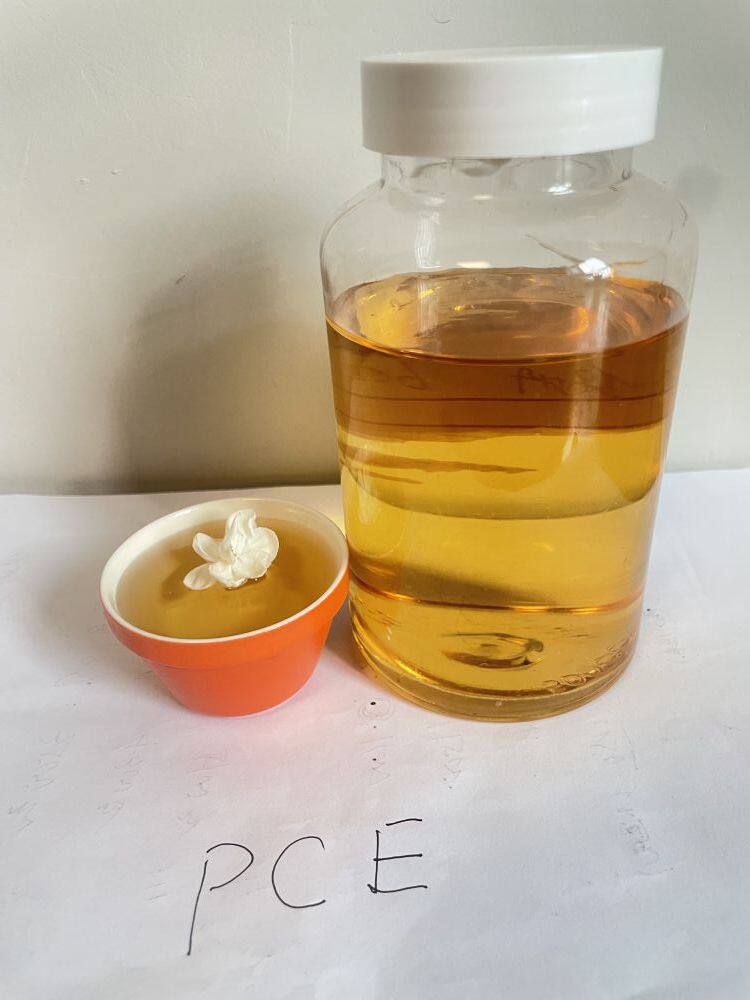

Usage Method of Polycarboxylate Superplasticizer (PCE)

2025-06-30 16:26:55

**Usage Method of Polycarboxylate Superplasticizer (PCE)**

The application of polycarboxylate superplasticizer (PCE) requires adjustments based on concrete mix design, construction requirements, and environmental conditions to ensure optimal performance. Below is a detailed **usage guide and key considerations**.

---

### **1. Dosage Range**

- **Recommended dosage**: Typically **0.1%~0.3%** of the cementitious materials (cement + mineral admixtures like slag or fly ash) by weight (calculated as solid content).

- **Low dosage (0.1%~0.2%)**: Suitable for ordinary concrete, with a water reduction rate of 15%~25%.

- **High dosage (0.2%~0.3%)**: Used for high-strength (C50+), self-compacting, or ultra-high pumping concrete, achieving 30%~40% water reduction.

- **Liquid PCE**: Convert based on solid content (e.g., 20% solid content requires 5× the dosage).

---

### **2. Application Methods**

#### **(1) Direct Addition (Most Common)**

- **Steps**:

1. Add PCE **simultaneously with mixing water** into the concrete mixer.

2. Extend mixing time by **20~30 seconds** compared to normal concrete to ensure uniform dispersion.

- **Advantages**: Simple operation, suitable for most commercial batching plants.

#### **(2) Delayed Addition (For Clay-Sensitive Aggregates)**

- **Steps**:

1. First mix 80% water and aggregates for 30 seconds.

2. Then add PCE with the remaining 20% water and continue mixing until uniform.

- **Applicability**: Reduces PCE adsorption loss when sand/gravel contains high mud content (>3%).

---

### **3. Key Control Parameters**

| Parameter | Recommended Range | Notes |

|----------------------|------------------------|-------|

| **Concrete Slump** | As per requirements (e.g., 180±20mm) | PCE is highly sensitive to water content—±5kg/m³ can significantly affect fluidity. |

| **Ambient Temp.** | 5~35°C | In high temperatures, add retarders; in low temperatures, avoid excessive retardation. |

| **Mixing Speed** | 15~20 rpm (forced mixer) | Low speed may cause uneven dispersion; high speed may entrain air. |

---

### **4. Compatibility Adjustments**

- **Cement Adaptability**:

- If **rapid slump loss** or **bleeding** occurs, adjust PCE molecular structure (e.g., switch between ether- or ester-based PCE).

- Test method: Fix PCE dosage and measure paste fluidity (30min loss ≤20% is acceptable).

- **Aggregate Effects**:

- For manufactured sand with high stone powder content, increase PCE dosage by 0.05%~0.1%.

- Pre-wet recycled aggregates to reduce water absorption impact.

---

### **5. Common Issues & Solutions**

| Issue | Possible Cause | Solution |

|---------------------|-----------------------|----------|

| **Rapid Slump Loss** | High C3A in cement | Use slow-release PCE or add retarders (e.g., sodium gluconate). |

| **Segregation/Bleeding** | Excessive PCE or low sand ratio | Reduce PCE by 0.05%~0.1%, increase sand ratio by 2%~3%. |

| **Abnormal Setting** | Retarder overdose/deficiency | Adjust retarder dosage (±0.01%~0.02%) based on temperature. |

---

### **6. Special Applications**

- **Ultra-High-Performance Concrete (UHPC)**:

- Dosage: 0.3%~0.5%, requires silica fume/fibers, extend mixing to 3~5 minutes.

- **3D-Printed Concrete**:

- Use low-viscosity PCE (0.2%~0.25%), initial slump: 50~100mm.

---

### **7. Safety & Storage**

- **Storage**:

- Liquid PCE: Store sealed at 5~40°C, avoid freezing (6-month shelf life).

- Powder PCE: Keep dry and dark (12-month shelf life).

- **Safety**:

- Rinse skin with water if contacted; seek medical help if ingested.

---

### **Conclusion**

Optimal PCE performance requires **compatibility testing** and **real-time adjustments**. Conduct **small trial batches** before full-scale use and monitor cement supplier changes (e.g., clinker composition). For complex projects (e.g., marine concrete), collaborate with admixture suppliers for customized formulations.

Tags: Polycarboxylate Superplasticizer, Polycarboxylate, PCE