-

Lily Lee

Hi there! Welcome to my shop. Let me know if you have any questions.

Lily Lee

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

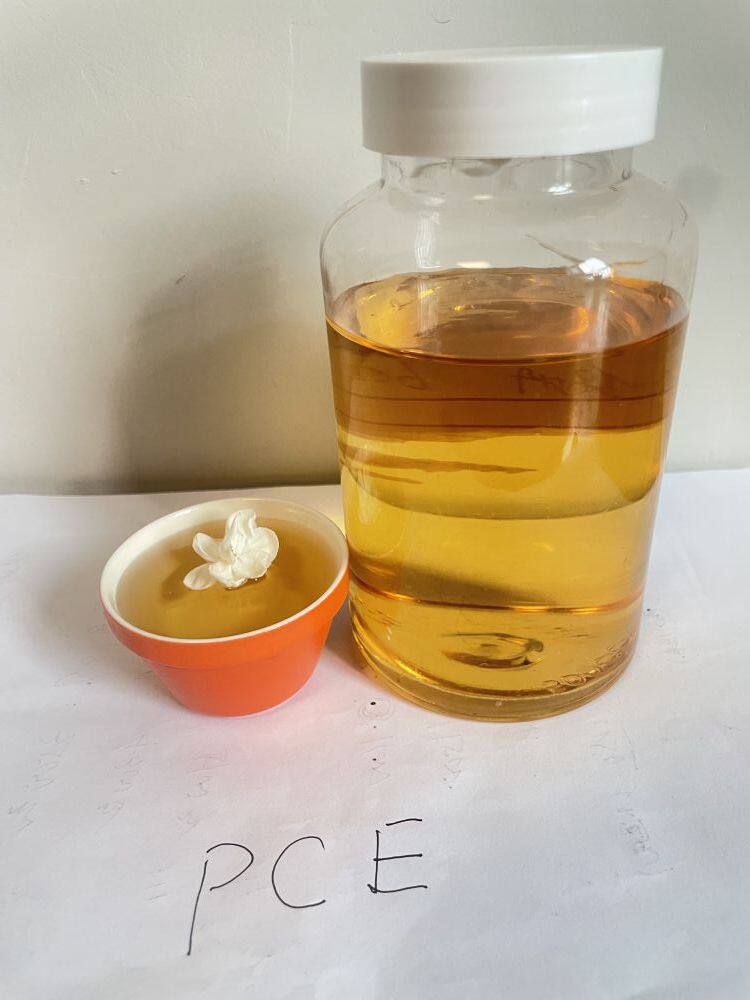

Introduction to Synthesis Process of Polycarboxylate Superplasticizer (PCE)

2025-06-30 16:05:12

### Introduction to Synthesis Process of Polycarboxylate Superplasticizer (PCE)

#### I. Main Synthesis Methods

1. **Free Radical Polymerization Process**

- Mainstream industrial production method

- Adopts aqueous solution polymerization system

- Reaction temperature: 40-80°C

- Common initiators: Ammonium/potassium persulfate (APS/KPS)

- Typical process parameters:

* Monomer concentration: 30-50%

* Reaction time: 3-6 hours

* Conversion rate >98%

2. **Controlled Radical Polymerization**

- ATRP (Atom Transfer Radical Polymerization)

- RAFT (Reversible Addition-Fragmentation Chain Transfer)

- Advantages: Narrower molecular weight distribution

- Challenges: Higher industrialization costs

#### II. Key Raw Material Systems

1. **Macromonomers**

- Main types:

* HPEG (Allyl polyoxyethylene ether)

* TPEG (Isopentenyl polyoxyethylene ether)

* APEG (Polyethylene glycol acrylate)

- Molecular weight selection: 1200-2400

2. **Functional Monomers**

- Acrylic acid/Methacrylic acid

- Maleic anhydride

- AMPS (2-Acrylamido-2-methylpropanesulfonic acid)

3. **Chain Transfer Agents**

- Thioglycolic acid

- 3-Mercaptopropionic acid

- Dosage: 0.1-1.5%

#### III. Process Flow

1. **Premixing Stage**

- Macromonomer dissolution (aqueous phase)

- Functional monomer preparation

- Initiator solution preparation

2. **Polymerization Reaction**

- Dripping methods:

* Synchronous dripping (monomer + initiator)

* Segmented dripping

- Temperature control: ±2°C precision

- pH adjustment: 6-8

3. **Post-treatment**

- Neutralization (NaOH/KOH)

- Dilution (Solid content 20-40%)

- Filtration (100-200 mesh)

#### IV. Process Optimization Directions

1. **Green Synthesis**

- Development of low-temperature initiation systems

- Reduction of organic solvent usage

- Application of bio-based monomers

2. **Intelligent Control**

- Online conversion rate monitoring

- Automated dripping systems

- AI-based reaction endpoint prediction

3. **Performance Customization**

- Molecular structure design:

* Comb density regulation

* Side chain length optimization

* Functional group introduction

#### V. Key Quality Control Points

1. **Key Indicators**

- Solid content: ±0.5%

- Water reduction rate: ≥25%

- Cement paste fluidity: ≥250mm

- Chloride ion content: <0.1%

2. **Characterization Methods**

- GPC for molecular weight measurement

- NMR for structure analysis

- HPLC for residual monomer monitoring

#### VI. Technology Development Trends

1. **Process Intensification**

- Application of continuous flow reactors

- Microwave-assisted polymerization

- Ultrasonic catalysis technology

2. **Functional Expansion**

- Slow-release PCE

- Clay-resistant PCE

- Early-strength PCE

3. **Composite Modification**

- Nanomaterial composites

- Organic-inorganic hybridization

- Multi-stimuli responsive types

Note: Actual production processes should be adjusted and optimized according to specific product performance requirements and production conditions. Small-scale trials are recommended before scale-up production.

Tags: Polycarboxylate Superplasticizer, Polycarboxylate, PCE